| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Hangyang

Model Number : KDN

Certification : CE/ASEM/GB

Place of Origin : China

MOQ : 1 set

Price : according to actual requirement

Payment Terms : negotiation

Supply Ability : according to actual requirement

Delivery Time : according to actual requirement

Packaging Details : wooden case, nude packing, container

Product Name : KDN-10000/100Y Nitrogen generation plant

Application : Glass,Oil and Gas Field,Machinery & Construction,Metallurgy

Output(Nm3/h) 8000~10000 : 8000~10000

Pressure(MpaG) : 0.7 MPa(G)

Material : Carbon steel, Al, stainless steel

Delivery Term : FOB Shanghai

Package : Seaworthy packing

Nitrogen generation plant 10000 Nm3/h/100 Nm3/h KDN-10000/100Y Lifting Gas Sealing Gas

Specifications:

Nitrogen Generation Plant KDN 8000~10000 Nm3/h Series

| MODEL CONTENTS | KDN-8000/200Y | KDN-9000/450Y | KDN-9000/130Y | KDN-8000/1000Y | |

| GAN/LIN flow | Nm3/h | 8000/200 | 9000/450 | 9000/130 | 8000/1000 |

| GAN/LIN purity | ppm | 5ppm(O2) | 5ppm(O2) | 3ppm(O2) | 3ppm(O2) |

| GAN/LIN pressure | MPa | 0.75 | 0.3 | 0.8 | 0.6 |

| Subcooled | ℃ | 13/-174 | 13/-173 | 13/-172 | 13/-174 |

Typical Product: KDN-10000/100Y Nitrogen generation plant

Output, purity and pressure

First operating mode:

|

| Flow (Nm3/h) | Purity | Pressure MPa(G) | Subcooled (℃) |

| GAN/LN | 10000 Nm3/h/100 Nm3/h | ≤1ppm(O2) | 0.7 | 13/-173 |

Description:

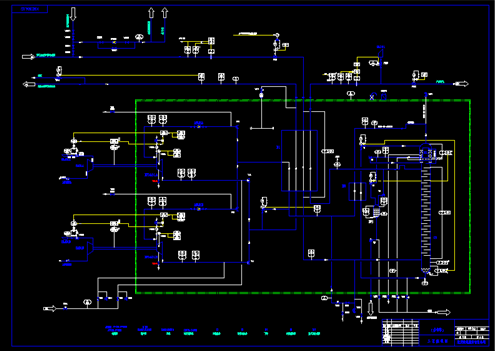

This plant employs a process in which the air is purified by molecular sieve, expansion turbine is provided with braking effected by blower and nitrogen is produced by means of single column with expansion accomplished through reflux.

After the feed air is cleaned of dust and mechanical impurities in air filter, it is compressed in air compressor to a pressure of approx 0.8MPa.

The compressed air is then fed into air pre-cooling system. When it is cooled to about 10℃, it becomes saturated.

The saturated and compressed air flows into switched molecular sieve adsorbers where such hydrocarbons as H2O, CO2 and C2H2 are adsorbed from the air.

A small part of purified process air is drawn out to be used as instrument air and the remainder is fed into main heat exchanger. The reflowed steam is cooled after being expanded to a saturation temperature and moisture- bearing to a certain extent, is throttled into the bottom of nitrogen column for participation in rectification. The nitrogen gas is then obtained at the top of nitrogen column while the saturated and oxygen-rich liquid air at the bottom of column is throttled into the evaporation side of condenser evaporator to condense the nitrogen gas at the top of column.

The saturated and oxygen-rich liquid air on the evaporation side of condenser evaporator, which is heated by the nitrogen gas at the top of column and evaporated to a saturated gaseous state, is drawn out, fed to the cold end of main heat exchanger and discharged after it is rewarmed to a normal temperature.

The expanded waste nitrogen flowing into main heat exchanger with a part of waste nitrogen out of liquid air subcooler is discharged out of cold box after it is rewarmed to a normal temperature; one steam is as the regenerated gas for the molecular sieve adsorber, the remainder is discharged.

The liquid nitrogen drawn out from the top of column is discharged out of cold box after it is throttled to a required pressure.

The nitrogen gas drawn out from the top of nitrogen column is discharged out of cold box after it is rewarmed in main heat exchanger and supplied to client.

In order to prevent hydrocarbon from accumulating in condenser evaporator, a small stream of liquid drawn from oxygen-rich liquid air evaporation side is discharged as waste liquid.

Applications:

Competitive Advantage:

|

|

Lifting / Sealing Gas Nitrogen Generation Plant / cryogenic nitrogen generation Images |